The main fields of research carried out by academics of the Department:

1. Research and development of quality control and management methods in industrial production.

2. Improving the efficiency of f standardization, certification and metrological support of production.

3. Development of competitive designs resource-energy-efficient metal-cutting tools.

4. Non-traditional technology of electricity production from renewable energy sources.

5. Provision of technological reliability of machine parts.

Academics of the Department improve their skills by taking part in special courses and workshops held both in Kazakhstan and abroad.

The department operates Student Design Bureau of Mechanical Engineering and Energy, established in accordance with the Rector's order of April 04, 2003. SDB performed development work in the following areas:

1 Non-conventional technologies of electric energy from renewable energy sources.

2 Development of competitive designs resource-energy-efficient metal-cutting tools

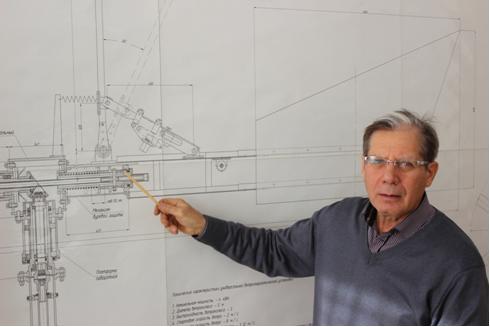

The SDB in mechanical engineering and energy are also carried out work on the s / b R&D number 29/1961 on the theme "Project of experimental-industrial sample of wind-power unit of average power". State budget R&D carried out by the grant of the MES RK totaling 4 million 200 thousand tenge in the period from October 2012 to December, 2014.

Photo - Universal windmill model, the study parameters of VC

Photo - Presentation of the project "Universal WM"to the Minister of Education of RK Sarinzhipov A.B. (scientific advice Professor Shumeyko I.A., master Nurkimbyaev S.M.)

Photo – Professor, Candidate of Technical Sciences., director of the Student Design Bureau of Mechanical Engineering and Energy Shumeyko I.A. explains the principle of power head work

Direction: Development of competitive designs resource-energy-efficient cutting tools participate professor Dudak N.S., associate professor Itybayeva G.T., Mussina Zh.K., Kassenov A.Zh., doctor PhD Taskarina A.ZH .

Objective: Development of resource-energy-efficient metal-cutting tools to ensure high quality surface treatment of machine parts with the development of new processing methods and designs of metalcutting tools.

Tasks:

1. The analysis of existing methods of processing of external and internal surfaces of machine parts;

2. Justification and development of new designs resource-energy-efficient new generation of cutting tools;

3. Develop recommendations for the treatment of external and internal surfaces of parts of machine resources, energy-efficient metal-cutting tools of the new generation.

Scientific results:

At the end of the results of the work done:

- Design, kinematics and dynamics processing resource-energy-efficient metal-cutting tools of the new generation;

- On the basis of experimental studies have established the effect of technological factors on the processing quality of the surfaces of machine parts resource-energy-efficient metal-cutting tools of the new generation;

- Technique of designing resource-energy-efficient metal-cutting tools of the new generation.

Photo - bimodal spiral drill bits without the core

Photo – vertical drill broaching

Photo – Sweep-broaching

Photos - incisal sweep with unfolding with peakless teeth

The practical significance lies in the fact that the constructions of the resource-energy-efficient metal-new generation of tools to ensure quality improvement processing, creation of favorable cutting conditions, a decrease in the tool material, which led to a reduction of resources and energy consumption, and, consequently, to a decrease of prime cost in the manufacture of the tool costs and details.

Intellectual property protection: An over 30 preliminary patents and patent innovation with the introduction of the production and training process.