The list of educational and laboratory equipment and technical training facilities available at the department corresponds to the educational goals and programs of the disciplines of the curriculum. A complete list of educational and production workshops, specialized classrooms and laboratories of the Department of Mechanical Engineering and Standardization

- B - 103, B-104 – Workshop of universal and specialized machines; - B-105 – Training workshop; - B-106 – Numerical control machines;

- B-107B – Laboratory of Metrology and Testing;

- B-108 – Training class of CNC machines;

- B-208 – Computer lab with all necessary software: Compass 3D, University Structures Bundle, etc. (opened in May 2025, 17 jobs);

- B-107B – Student Design Bureau for Mechanical Engineering and Power Engineering;

- B-211 – Cabinet of engineering technology;

- B-210 – opened under the Roadmap program in the framework of cooperation with Prommashkomplekt LLP, the Specialized Auditorium of Prommashkomplekt LLP and R.W.S. Wheelset LLP (the auditorium was opened in September 2018), followed by equipping the manufactured products of Prommashkomplekt LLP;

- B-217 – Auditorium of metal-cutting tools named after Professor Dudak Nikolay Stepanovich" (the auditorium was opened in September 2017).

Next year, it is planned to open a new laboratory B-137 – Training workshops for modern CNC machines. At the moment, the equipment is being prepared for launch (Fanuc OiMF(5) PLUS Vertical machining center, SK6150 CNC Lathe) and the auditorium is undergoing major repairs.

The list of available universal and specialized technological equipment, measuring instruments and tools: Turning and screw-cutting machine model 1K62; Turning and screw-cutting machine model 1A616; Vertical drilling machine model 2A135; Vertical milling machine 6P11; Vertical milling machine 6L12P; Horizontal milling machine 6H81; Transverse planing machine model 7M36; Machine cutting saw blade model 872P; Tooth milling machine model 5310; Tooth cutting machine model 5B12; Tooth cutting machine 5236P; Surface grinding machine 3C71; Grinding machine ZA64M; Grinding machine 3641; metalworking machine (cutting pendulum SOM-400B); Desktop drilling machine NS-12B; Locksmith workbenches with a vise; Turning and screw-cutting machine model 16K20F3R132; Turning and screw-cutting machine model FT-23; Inverter plasma cutter; Electric air compressor; Grinding machine STALEX DS-300/1 STAND; Frequency converter; Turning and screw-cutting machine model 16K20F3; Vertical milling machine model 6R13F3; Drilling and milling machine 2206VMF2; Microscope UIM-21; Horizontal optimeter IKG-3; Evolvent meter BV-584M; TALYROND round gauge; BV-1089 gear pitch measuring device; MTS320M device; BP-500 Bieniometer; MIS-11 Linnik double microscope; BMI microscope; Vertical optical measuring device; B-10M device; BV-3023/100 device; DIN-1 dynamometer; TIME roughness meter TR210; Strain gauge measuring system ZET-058; Anemometer optical; Vibration analyzer VP-3470; BALTECH vibration pen VP-3407-3; S-shaped force sensor; Flat force sensor; Roughness meter TR110; Roughness meter TR3200; Electronic indicator IC 0-25; Microinterferometer Linnik MII-4M; Digital microhardness meter; Ultrasonic hardness tester TKM-459M; Pyrometer BALTECH TL-0215 C; Tachometer SEM AT-8; Thermal imager BALTECH; Zubr Expert (electronic caliper); Shtangenreysmas SHR-40-400; Digital micrometer MCC 0-25; Nutrometer NI 10-18; Nutromer NI 18-35; Nutromer NI 35-50; Nutromer NI 50-160; Universal angle gauge; Lever tooth gauge; Roughness samples; End length measures; Flexible magnetic stand CHIZ MS-29; Tripod for measuring heads CHIZ SHM-3; Type 2 protractor with vernier; Laboratory for virtual study and experimental research of metal-cutting machines (interactive training module); Desktop training lathe with a computer-controlled CNC system UTS4–CNC; Desktop milling machine with computer control UFSp-CNC - USB; Training welding complex TDS-02; Welding transformer TDM-305; 3D printer W200; Reeyee PRO 3D scanner; UMT-200 Universal friction machine; Wear and lubrication quality tester; Contrast microscope; Kistler sensor; Brinell reference microscope.

Photo 1 – Training workshop and students during the training (locksmith) practice

Photo 2 – Workshop of universal and specialized machines (general view)

Photo 3 – Workshop of universal and specialized machines (machines of various types)

Photo 4 – Instruments in the B-107B "Metrology and Testing" laboratory

Photo 5 – Equipment and devices in B-108 "Numerical control machine tool classroom"

Photo 6 - The Cabinet of metal cutting tools

Information and Methodological Support and Library Services

Information, methodological and library equipment In all disciplines of the educational programs 6B07102 – Mechanical Engineering, 6B07501 – Standardization, certification and Metrology (by industry), 7M07103 – Mechanical Engineering, 7M07501 - Standardization, certification and Metrology (by industry), 8D07101, 8D07151 – Mechanical engineering, there is a 100% provision of both library literature and literature in the state and Russian languages. The accumulated 50 years of training experience, methodological support of the educational process, the material and technical base, and the personnel potential of the department make it possible to train highly qualified engineering personnel taking into account the restructuring processes in the economy of the Republic of Kazakhstan. In organizing the educational process, the department proceeds from two main objectively valid factors: scientific and technological progress and developing market relations. These factors form the basis for the creation of a modern specialist model, which determines the ideological orientation of her scientific and pedagogical activities.

The main directions of the scientific work of the department are:

1. Research and development of new methods of quality control and management of industrial products.

2. Improving the efficiency of standardization, certification and metrological support of production.

3. Development of competitive designs of resource-efficient metal cutting tools.

4. Development and research of wind power plants.

5. Ensuring the technological reliability of machine parts.

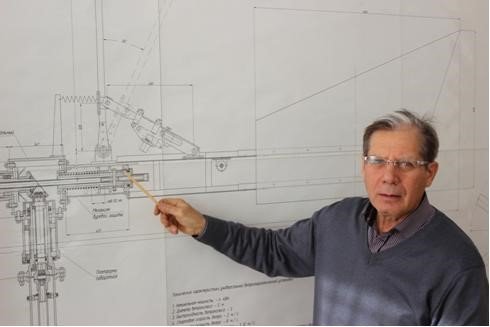

The department has organized scientific and methodological seminars conducted by the faculty of the department. Topics considered: "10 kW wind power plant" (Speaker, Ph.D., Professor I.A. Shumeyko), Explanation of the project "Comprehensive Plan for the development of mechanical Engineering in the Republic of Kazakhstan for 2019-2023": goals, objectives, analysis of the current situation and further development of mechanical engineering in Kazakhstan (Speaker, Ph.D., Associate Professor (Assoc.) A.J. Kasenov).

In order to improve their skills, all teachers of the department regularly participate in courses and seminars held in Kazakhstan and neighboring countries. The department has a student design bureau for mechanical engineering and power engineering, established in accordance with the Rector's order dated April 04, 2003.

Development work is being carried out in SKB in the following areas:

- Non-traditional technologies for generating electric energy based on renewable energy sources. The student Design bureau for Mechanical Engineering and Energy has developed projects and manufactured operating models of wind power plants.;

- a wind-lifting unit with a capacity of 4 liters/min;

- wind power plant with a capacity of 120 watts.

- experimental studies of the dependence of the moment of rotation speed and power on the design parameters of a wind wheel have been performed;

- the design parameters of the wind wheel have been identified to ensure maximum values of torque, rotational speed and power; - technical and operational projects of a low-power wind turbine have been completed; - some parts of the wind turbine are manufactured;

- the project was completed and a model of a 0.12 kW wind turbine was manufactured to test the operation of the wind turbine in the electric station mode.

Photo 7 – Current model of a wind power plant, study of WW parameters

Photo 8 – Professor, Candidate of Technical Sciences, head of the Student Design Bureau for Mechanical Engineering and power engineering I.A. Shumeyko explains the principle of operation of the power head

Head of the department Musina Zh.K., Professor Itybayeva G.T., Professor Kasenov A.Zh. are participating in the development of competitive designs of resource-saving metal-cutting tools. Objective: To develop resource-efficient metal-cutting tools that ensure high-quality surface treatment of machine parts with the development of new processing methods and designs of metal-cutting tools.

Tasks:

1. Analysis of existing methods of processing the external and internal surfaces of machine parts;

2. Substantiation and development of new designs of resource-efficient metal cutting tools of a new generation;

3. Development of recommendations for processing the external and internal surfaces of machine parts with resource-saving metal cutting tools of a new generation.

Scientific results. Based on the results of the work done, the results were obtained:

- designs, kinematics and dynamics of the processing process with resource-saving metal cutting tools of a new generation;

- based on experimental studies, the influence of technological factors on the quality of surface treatment of machine parts with resource-saving and energy-saving metal cutting tools of a new generation has been established.;

- methods of designing resource-saving metal cutting tools of a new generation.

Photo 9 – Double-ended spiral drills without a transverse edge

Photo 10 – Countersink-broach

Photo 11 – Sweep-broach

Photo 12 – Incisor sweep with topless teeth

The practical significance lies in the fact that designs of resource-saving metal-cutting tools of a new generation have been developed to improve the quality of processing, create favorable cutting conditions, and reduce tool material, which has led to a reduction in resources and energy consumption, and, consequently, to a reduction in the cost of manufacturing tools and parts. Intellectual property protection: Over 35 preliminary patents and innovative patents have been obtained with implementation in production and the educational process. In the 2024-2025 academic year, under the guidance of Ph.D., Professor I.A. Shumeiko, the research and development of parameters and design of low-power wind power plants was carried out. The percentage of completion of the 0.3 kW prototype is 90%, a methodology has been developed for planning and conducting experimental studies to assess the degree of influence of the design parameters of the wind wheel on the moment and power developed by the wind wheel. He was a consultant to the doctoral student Nurkimbaev S.M. for the degree of Doctor of Philosophy PhD in OP 8D07101 - Mechanical Engineering on the topic of the dissertation "Improving the efficiency of wind power plants based on the study of design parameters." He was the supervisor of the master's thesis of undergraduate Meirbek R. on the topic "Research of parameters and design development of a unit for lifting groundwater with a storm protection". The dissertation was successfully defended.

Since 2024, the department has been working on the development of a set of measures for the instrumental support of the manufacturing sectors of the economy of the Republic of Kazakhstan within the framework of the Scientific Research Center IRN BR24993003. As part of the implementation of the TPF, in December 2025, Tatyana Leonidovna Lub doctoral dissertation for the degree of Doctor of Philosophy (PhD) will be defended on the topic: "Study of the accuracy of rotary machining with a tool with a self–rotating cutting edge", specialty 8D07101 - "Mechanical Engineering".

Tel: 673633 (int. 1201)